Polyurethane foam and water-based polyurethane, are you "made" in detail?

- Categories:Industry News

- Author:不详

- Origin:新材料在线

- Time of issue:2018-04-02

- Views:4

(Summary description)Polyurethane foam (PUF) is a plastic foam material formed by the reaction of isocyanate and polyol to form a polymer with a repeating unit of urethane, which is formed under the action of a blowing agent.

Polyurethane foam and water-based polyurethane, are you "made" in detail?

(Summary description)Polyurethane foam (PUF) is a plastic foam material formed by the reaction of isocyanate and polyol to form a polymer with a repeating unit of urethane, which is formed under the action of a blowing agent.

- Categories:Industry News

- Author:不详

- Origin:新材料在线

- Time of issue:2018-04-02

- Views:4

Polyurethane (PU) is the abbreviation for polyurethane. Any polymer compound containing many repeating -NHCOO- groups on the polymer backbone is collectively referred to as polyurethane.

1. Polyurethane foam

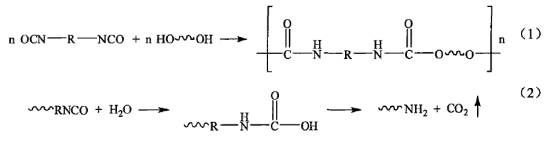

Polyurethane foam (PUF) is a plastic foam material formed by the reaction of isocyanate and polyol to form a polymer with a repeating unit of urethane, which is formed under the action of a blowing agent. Because of its large output and mature technology, it is widely used in refrigeration, decoration, construction, packaging, automotive and other industries.

1. The foaming principle of polyurethane foam

From the perspective of colloidal chemistry, the foam formation principle of polyurethane includes three aspects: foam formation, growth and stability.

(1) The formation of bubbles

Under the action of high-speed stirring, the materials are quickly mixed evenly. The isocyanate reacts with water to generate CO2 gas, and the physical blowing agent is heated and vaporized, so that the gas concentration in the material increases and reaches a saturated state; then the gas escapes from the liquid phase to form a fine bubble-nucleation process. The generated bubbles remain in the solution, making the material white, and the end point is that no new bubbles are generated.

(2) The growth of bubbles

After the foam is formed, there is still new gas continuously produced in the material. It penetrates into the formed bubbles from the liquid phase, which causes the cells to expand, and some bubbles merge and cause the cells to expand. At this time, the internal pressure of the bubble increases, and the viscous liquid layer becomes thinner. When there is no new gas infiltration, the foam stops growing.

(3) Stability of foam

In the foam growth stage, the bubble wall layer becomes thinner, which may cause instability of the foam. When the gas in the bubble increases and the internal pressure gradually increases, if the strength of the bubble wall is not high, the gas will break through the wall mold and cause the foam to collapse. Using a proper amount of surfactant (silicone oil) can reduce the surface tension of the bubbles, which is beneficial to the formation of fine bubbles, weaken the gas diffusion, and increase the strength (elasticity) of the bubble wall can also promote the stable growth of the foam.

The biggest feature of polyurethane foam is the adaptability of the product, and its performance can be adjusted in a wide range. Such as changing the chemical composition and structure of raw materials, the ratio of various components, adding various additives, synthesis conditions and process methods, etc., can be produced with different hardness, chemical resistance, temperature resistance, and flame resistance. And various foam plastics with high mechanical strength.

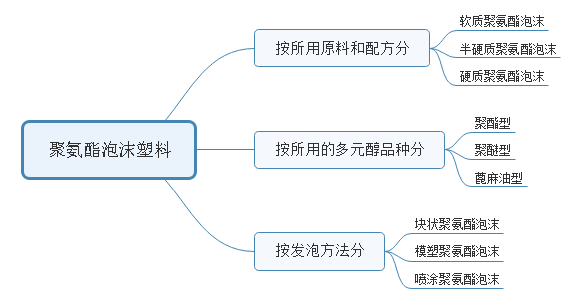

2. Classification of polyurethane foam

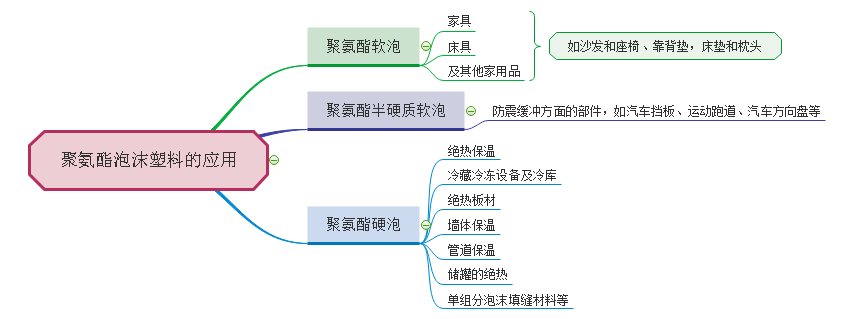

Foam plastic is one of the main varieties of polyurethane synthetic materials. Its main feature is porosity, so its relative density is low and its specific strength is high. The main categories are as follows:

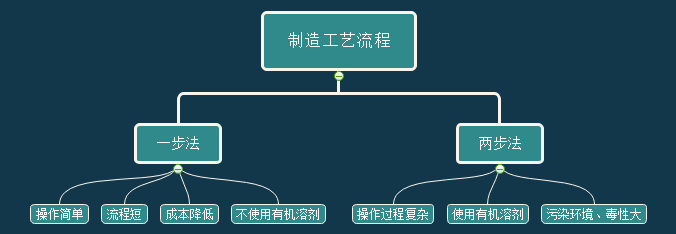

But no matter what kind of production process, the process includes the following two main reactions: gel reaction and foaming reaction.

Scan the QR code to read on your phone

Recommended News

NANTONG RIYUE

Nantong RiYue CNC Machine CO.,LTD.

Service:

Add:

Rugao City, Jiangsu Province, CHINA.

Copyright © 2021 Nantong RiYue CNC Machine CO.,LTD. 苏ICP备09043456号

Whatsapp

Whatsapp

E-mail

E-mail Tel

Tel